| Thick | Inch | Width | Length | Sheets | Cases | M2 | Nett | Container |

| (mm) | per | (mm) | (mm) | per | per | per | Weight | Type |

| Pcs | Case | Ctr | Ctr | 20'Ctr | ||||

| 3mm | 59*79" | 1500 | 2000 | 105 | 10 | 3150.00 | 23625.00 | close top |

| 60*84" | 1525 | 2134 | 100 | 10 | 3254.35 | 24407.63 | close top | |

| 72*96" | 1830 | 2440 | 83 | 9 | 3335.50 | 25016.28 | close top | |

| 65*87" | 1650 | 2200 | 83 | 11 | 3314.19 | 24856.43 | close top | |

| 84*130" | 2140 | 3300 | 43 | 10 | 3036.66 | 22774.95 | close top | |

| 3.2mm | 84*130" | 2140 | 3300 | 40 | 10 | 2824.80 | 21186.00 | close top |

| 4mm | 72*96" | 1830 | 2440 | 53 | 10 | 2366.56 | 23665.56 | close top |

| 84*130" | 2140 | 3300 | 33 | 10 | 2330.46 | 23304.60 | close top | |

| 89*130" | 2250 | 3300 | 33 | 10 | 2450.25 | 24502.50 | open top | |

| 84*144" | 2140 | 3660 | 30 | 10 | 2349.72 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 30 | 10 | 2470.50 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 30 | 9 | 2411.21 | 24112.08 | open top | |

| 5mm | 72*96" | 1830 | 2440 | 43 | 10 | 1920.04 | 24000.45 | close top |

| 84*130" | 2140 | 3300 | 26 | 10 | 1836.12 | 22951.50 | close top | |

| 89*130" | 2250 | 3300 | 26 | 10 | 1930.50 | 24131.25 | open top | |

| 84*144" | 2140 | 3660 | 24 | 10 | 1879.78 | 23497.20 | close top | |

| 84*144" | 2134 | 3660 | 24 | 10 | 1874.51 | 23431.32 | close top | |

| 89*144" | 2250 | 3660 | 24 | 10 | 1976.40 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 24 | 9 | 1928.97 | 24112.08 | open top |

Detaile and Description

Features:

1) Defects numbers in 1 square meter: 0 (diameter >0.01mm)

2) Light transmission for transparent glass: >85%

3) Zebra angle: <45 degrees

4) Thickness uniformity is excellent, and the minimum thickness deviation can

be controlled within 0.08mm

5) The accuracy of cutting size is high and can be controlled within 1mm

6) Visible flaw is controlled strictly; quality of all kinds of products can be

provided according to the requirements of customers

Quality level: automotive level, comply with China National Norm

GB11614-1999

Specifications: Thickness: 2-22mm

Features:

1) Defects numbers in 1 square meter: 0 (diameter >0.01mm)

2) Light transmission for transparent glass: >85%

3) Zebra angle: <45 degrees

4) Thickness uniformity is excellent, and the minimum thickness deviation can

be controlled within 0.08mm

5) The accuracy of cutting size is high and can be controlled within 1mm

6) Visible flaw is controlled strictly; quality of all kinds of products can be

provided according to the requirements of customers

Quality level: automotive level, comply with China National Norm

GB11614-1999

Specifications: Thickness: 2-22mm

| Thick | Inch | Width | Length | Sheets | Cases | M2 | Nett | Container |

| (mm) | per | (mm) | (mm) | per | per | per | Weight | Type |

| Pcs | Case | Ctr | Ctr | 20'Ctr | ||||

| 6mm | 72*96" | 1830 | 2440 | 36 | 10 | 1607.47 | 24112.08 | close top |

| 84*130" | 2140 | 3300 | 22 | 10 | 1553.64 | 23304.60 | close top | |

| 84*130" | 2134 | 3300 | 22 | 10 | 1549.28 | 23239.26 | close top | |

| 89*130" | 2250 | 3300 | 22 | 10 | 1633.50 | 24502.50 | open top | |

| 84*144" | 2140 | 3660 | 20 | 10 | 1566.48 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 20 | 10 | 1647.00 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 20 | 9 | 1607.47 | 24112.08 | open top | |

| 8mm | 72*96" | 1830 | 2440 | 27 | 10 | 1205.60 | 24112.08 | close top |

| 84*130" | 2140 | 3300 | 16 | 10 | 1129.92 | 22598.40 | close top | |

| 89*130" | 2250 | 3300 | 16 | 10 | 1188.00 | 23760.00 | open top | |

| 84*144" | 2140 | 3660 | 15 | 10 | 1174.86 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 15 | 10 | 1235.25 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 15 | 9 | 1205.60 | 24112.08 | open top | |

| 10mm | 72*96" | 1830 | 2440 | 22 | 10 | 982.34 | 24558.60 | close top |

| 84*130" | 2140 | 3300 | 13 | 10 | 918.06 | 22951.50 | close top | |

| 89*130" | 2250 | 3300 | 13 | 10 | 965.25 | 24131.25 | open top | |

| 96*130" | 2440 | 3300 | 13 | 9 | 942.08 | 23552.10 | close top | |

| 84*144" | 2140 | 3660 | 12 | 10 | 939.89 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 12 | 10 | 988.20 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 12 | 9 | 964.48 | 24112.08 | open top | |

| 12mm | 84*130" | 2140 | 3300 | 11 | 10 | 776.82 | 23304.60 | close top |

| 89*130" | 2250 | 3300 | 11 | 10 | 816.75 | 24502.50 | open top | |

| 96*130" | 2440 | 3300 | 10 | 10 | 805.20 | 24156.00 | close top | |

| 84*144" | 2140 | 3660 | 10 | 10 | 783.24 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 10 | 10 | 823.50 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 10 | 9 | 803.74 | 24112.08 | open top | |

| 15mm | 84*130" | 2140 | 3300 | 9 | 10 | 635.58 | 23834.25 | close top |

| 89*130" | 2250 | 3300 | 9 | 10 | 668.25 | 25059.38 | open top | |

| 96*130" | 2440 | 3300 | 8 | 10 | 644.16 | 24156.00 | close top | |

| 84*144" | 2140 | 3660 | 8 | 10 | 626.59 | 23497.20 | close top | |

| 89*144" | 2250 | 3660 | 8 | 10 | 658.80 | 24705.00 | open top | |

| 96*144" | 2440 | 3660 | 8 | 9 | 642.99 | 24112.08 | open top | |

| 19mm | 84*130" | 2140 | 3300 | 7 | 10 | 494.34 | 23481.15 | close top |

| 89*130" | 2250 | 3300 | 7 | 10 | 519.75 | 24688.13 | open top | |

| 84*144" | 2140 | 3660 | 6 | 10 | 469.94 | 22322.34 | close top | |

| 89*144" | 2250 | 3660 | 6 | 10 | 494.10 | 23469.75 | open top | |

| 96*144" | 2440 | 3660 | 6 | 9 | 482.24 | 22906.48 | open top |

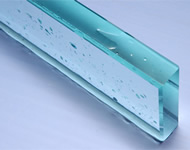

Float glass is a sheet of glass made by floating molten glass on a bed of molten tin. The term “float” glass derives from Sir Alastair Pilkington, the man who developed the process between 1953 and 1957, together with Kenneth Bickerstaff of the U.K.’s Pilkington Brother. It was the first successful commercial application for forming a continuous ribbon of glass using a molten tin bath on which the molten glass flows laterally, unhindered to the limit of its free flow under the influence of gravity and surface tension. About 90% of the world’s flat glass is currently formed via the float method, which produces glass with extremely flat, parallel surfaces.

ABOUT US

FACTORY OVERVIEW

EXHIBITION

DOWNLOAD CENTER

PRODUCTS & SERVICE

CERTIFICATION

TECHNICAL SUPPORT

ORDER TRACKING

PROJECTION

OEM DESIGN

HUMAN RESOURCE

JOB & POSITION

CONTACT US

PEC QINGDAO ALUMINUM INDUSTRY CO.,LTD©Copyright